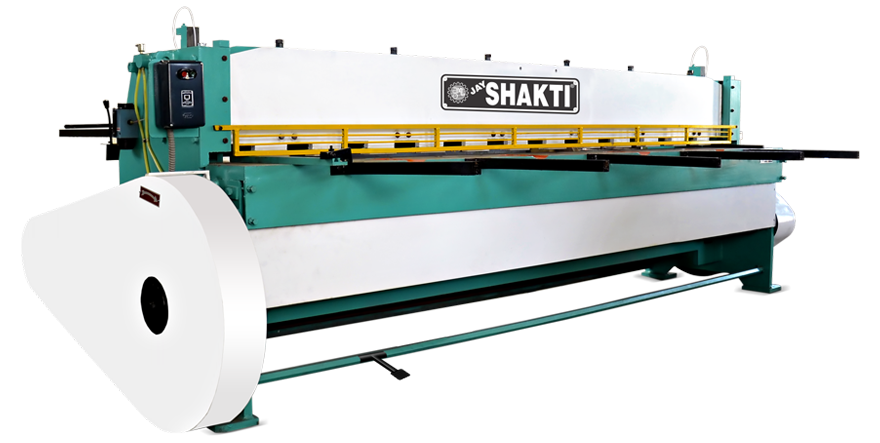

Under Crank Mechanical Shearing Machine

In this international market, our organization is recognized as a most prominent manufacturer, exporter and supplier of Mechanical Under Crank Shearing Machine. The offered machine is manufactured by making use of excellent quality steel alloy sheets of uniform thickness for its frame structure and high grade components for its efficient functioning. The provided shearing machine is applied for cutting metal sheets. In order to be used for varied applications, this machine is available in various standard models with essential specifications. Moreover, our valued clients can avail this Mechanical Under Crank Shearing Machine at market competitive prices.

Features:

|

|

| Further Details :- | "JAY SHAKTI " Brand Under Crank Shearing Machine is suitable for cutting to size general purpose and alloyed structural steel sheets up to 4 MM thickness,with high productivity. Design to the most accurate standards of efficiency,offers out standing operational performance and dimensionally accuracy telling on high out put and dependability. |

| Construction :- | All "Jay Shakti" Guillotine Shears are fabricated from IS 2062 Grade Rolled steel plates, Table and cutting beams are deeply reinforced and finished machines after stress relieving. The Inter Lock Design put the direct support to frame thus frame is strain free and eliminates welds at load supports thus the accuracy of the machine is never disturbed |

| Clutch & Brake :- | The all shears are provided with Rolling key Type clutch, from alloy steel. The clutch is gives continuous stroke for mass productions.Brake is provided on the main shaft giving sufficient adjustment to increase the performance and accuracy. |

| Hold down System :- | All shears are provided with spring loaded Holding pads. All spring loaded pads maintains a positive and uniform pressure along the full length of the work piece preventing slippage, Regardless of the thickness Variation. |

| Blades :- | Jayshakti Shears are provided with high quality single segment (HcHcr) Blades for longer tool life. Ease in assembling of knife reduces down - time. The shear blades are four edged. |

| Lubrication :- | All bearing parts and guide surfaces are lubricated through hand-operated lubrication system. |

| Mechanical Back gauge :- | This is a standard equipment provided on all Jay Shakti shears. Scale on the back gauge gives instantaneous reading of distance between shear and back gauge. Thus avoiding errors and maintenance encountered in electronic equipment. |

STANDARD ACCESSORIES:

|

|

OPTIONAL ACCESSORIES:

|

|

TECHNICAL SPECIFICATION

| Model | Cutting Cap.In MS Length X Thickness | Stroke Per Minute (Nos.) | Table Height | Table Width | Front Gauge | Back Gauge | Motor (HP /Rpm) | Size Of Blade | Over All Dimension | ||||

| Length | Width | Thickness | Length | Width | Height | ||||||||

| JSUS - 1 | 1250 X 2 | 55 | 850 | 400 | 500 | 500 | 3 / 1440 | 1270 | 60 | 14 | 2100 | 1900 | 1300 |

| JSUS - 2 | 1525 X 2 | 55 | 850 | 400 | 500 | 500 | 3 / 1440 | 1550 | 60 | 14 | 2360 | 1900 | 1300 |

| JSUS - 3 | 2030 X 2 | 55 | 850 | 400 | 500 | 500 | 5 / 1440 | 2050 | 60 | 14 | 2825 | 1900 | 1300 |

| JSUS - 4 | 2540 X 2 | 55 | 850 | 400 | 500 | 500 | 7.5 / 1440 | 2550 | 60 | 14 | 3325 | 1900 | 1300 |

| JSUS - 5 | 3125 X 2 | 55 | 850 | 400 | 500 | 500 | 10 / 1440 | 3150 | 62 | 18 | 3190 | 1900 | 1300 |

| JSUS - 6 | 1250 X 4 | 50 | 900 | 450 | 600 | 600 | 5 / 1440 | 1270 | 62 | 18 | 2300 | 2000 | 1350 |

| JSUS - 7 | 1525 X 4 | 50 | 900 | 450 | 600 | 600 | 5 / 1440 | 1550 | 62 | 18 | 2550 | 2000 | 1350 |

| JSUS - 8 | 2030 X 4 | 50 | 900 | 450 | 600 | 600 | 7.5 / 1440 | 2050 | 62 | 18 | 3100 | 2000 | 1350 |

| JSUS - 9 | 2540 X 4 | 50 | 900 | 450 | 600 | 600 | 10 / 1440 | 2540 | 75 | 18 | 3600 | 2000 | 1350 |

| JSUS - 10 | 3125 X 4 | 50 | 900 | 450 | 600 | 600 | 12.5 / 1440 | 3150 | 75 | 18 | 4200 | 2000 | 135 |